CATEGORIES

- Motor machinery for Stator

- Motor machinery for Armature

- Motor machinery for Rotor

- Motor parts

- Heat treatment varnish Oven

- Induction cooker machinery

Latest news

- Motor Manufacturers Clinet visit in th

- Motor Testing equipment in Shanghai Ch

- Motor efficiency improvement is an imp

- Hybrid electric vehicle Hairpins New e

- How to produce a big 12KGS Bruless Mot

- Power Coating For Motor Insulation Ele

Contact us

- ADD: No.4 Building , No.1500, Kongjiang Road,Yangpu District,200093,Shanghai,China Skype: motor.machinery

- TEL: 86-21-58992293

- FAX: 86-21-58992292

- E-mail: [email protected]

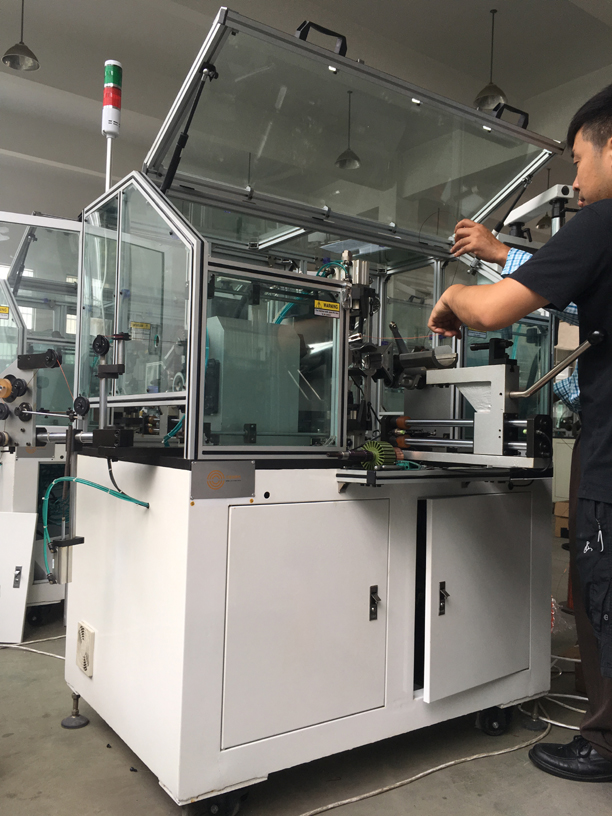

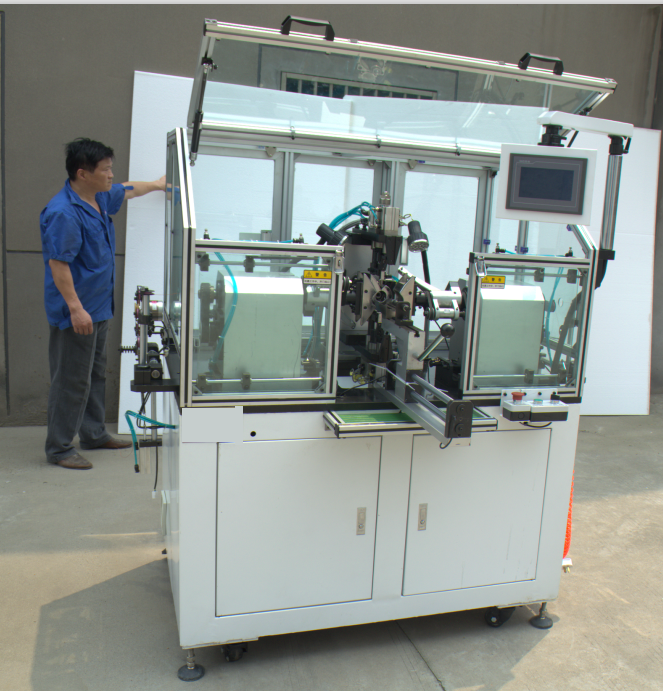

Riser commutator armature winding machine Armature winder for slot type commutator Vacuum cleaners hammers power tool WIND-ST-TD2B

- Slotted type armature winder

- Wire diameter: 0.20~1.2mm

- Slotted comm cross connection

- Max wire 1.35mm (AWG16)

- Product description: Armature winder for slotted type commutator armature,Vacuum cleaners hammers power tool Armature winder for slot type commutator,

PRODUCT INTRODUCTION

Slotted type commutator with or without risers commutator armature winding machine Slot type commutator rotor armature wider

WIND-ST-TD2B Advantages:

1. Slot type armature with thin, thick wire machine can handle,

Machine had good feedback of winding a 0.25mm wire diameter armature

2. Have good adaption for slot type commutator with groove,

No need to work with special designated slot machine

3. Got good feedback in wide application from customers

4. 98% yield rate above assured when the slot commutator quality is good

5. Till now it is the best machine in China for winding slot type armature

Straight stack Armature Winding Video:

Skew armature winder

Armature winder under commissioning

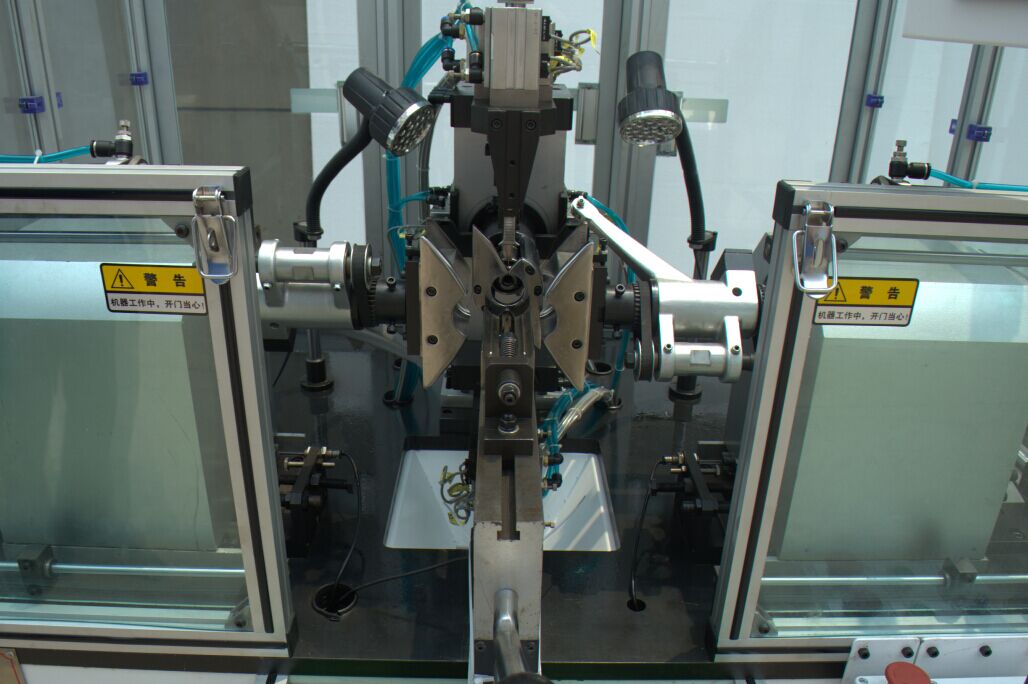

Slotted type armature winder tooling

Main data:

Wire diameter: 0.20~1.2mm

Armature diameter range:20~90mm

Armature stack length:10~130mm

Commutator diameter:8~60mm

Armature slot number:Odd, oven slot

Turns no.:0~99999

Flier fork speed:0~2000RPM

Indexing speed:0~2500RPM

Total power:4.5KW

Operation method:Step, Auto, JOG

Power source:AC380V 50/60Hz

Air source:5~7KG/cm2

Weight:850KGS

Dimension:1530mm x 1280 mm x 1650mm

Main configuration:

PLC: MITSUBISHI

Servo control system: Delta

Touch screen: MCGS7062KS

Pneumatic system: AIRTAC

Main electrical components:Korea and Japan

Tension :Hysteresis tension

Linear guide way: HIWIN

Safety door and feeding device: Pneumatic

WIND-ST-TD2B winding machine is to do winding for the armature with riser type commutator. It has double flyer to make the winding and with auto wire cutting, clamping structure, assisting wire inserting way to upgrade the winding speed.

Tags:

Slotted type commutator with and without risers winding,

hammer motor armature winding,

Contact: [email protected]

Skype: motor.machinery

Mobile: +86-17721374887

Website: http://www.motor-machinery.com; http://www.coilswinding.com

| Lap winding with double flyer wire gauge range | Usually 0.20~1.2mm, Max machine handled 1.35mm (about AWG16) |

| Armature commutator type | Slotted type riser type not hook type |

| Automatic or semi automatic |

You only need to load and unload armature, other actions such as hooking, winding, indexing and cutting are wound by machine automatcially

Wire size and Wire slot size(Length,width and depth), the wire slot should have enough space for the wire to stay inside Wire size 17AWG (1.15 mm), Slot: blade width 1.143, length=7.14 mm, depth= 5.95 mm and we think if the depth is bigger, the wire can acquire more space to stay inside slot, while depth is more, length is more too, 4.2 Could you please check if the commutator was pressed consistanctly each time at same location according armature stack? The push pin witness marks on the commutator are consistent. Because armature commutator and stack position is very important for indexing consistantly Fully automatic winding machine with Japan as the pioneer, the rising demand for high quality products and low labor cost, operator only need to ensure enough raw materials, and replace them in time without workpiece or copper wire, so that continuous production can be ensured. The number of shaft is usually high, so as to achieve high efficiency production. A machine with enough automation can meet the requirements of an employee handle two or three winding machines at the same time.

|

Pearl

Pearl Emily

Emily