CATEGORIES

- Motor machinery for Stator

- Motor machinery for Armature

- Motor machinery for Rotor

- Motor parts

- Heat treatment varnish Oven

- Induction cooker machinery

Latest news

- Motor Manufacturers Clinet visit in th

- Motor Testing equipment in Shanghai Ch

- Motor efficiency improvement is an imp

- Hybrid electric vehicle Hairpins New e

- How to produce a big 12KGS Bruless Mot

- Power Coating For Motor Insulation Ele

Contact us

- ADD: No.4 Building , No.1500, Kongjiang Road,Yangpu District,200093,Shanghai,China Skype: motor.machinery

- TEL: 86-21-58992293

- FAX: 86-21-58992292

- E-mail: [email protected]

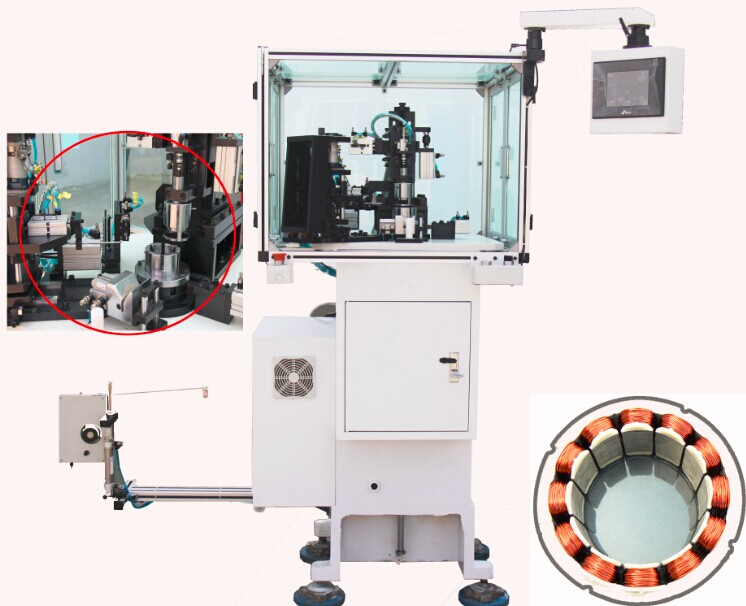

Stator Needle Winding Machine

- Three Needle Winding

- Servo Motor and Cam Device

- Product description: Brushless motor stator winding machine can wind muti-pole stator of air conditioner compressor, refrigerator compressor,water pump automotive application , fuel pump with 6poles,9poles,12poles, needle

PRODUCT INTRODUCTION

Brushless DC motor stator needle winding machine WIND-3A-TSM Advantages:

1. Suitable for 6poles,9poles,12poles BLDC stators.with same winding diagram of three phases.

2. Especially suitable for thick wire diameter around 0.8mm brushless stator winding

3. Achieve good feedback from customers and respected SAMSUNG ordered 4pcs

4. Needle winding speed for wire size 0.08~0.3mm, can wind at 350RPM~400RPM

for wire size 0.3~1.0mm, can wind at 400RPM~450RPM

For a 12 poles stator, with 105 turns and wire diameter around 0.5~0.8mm,

the cycle time is 60~70s/ps, the productivity per shift is 480pcs/8 hours

Feature:

Brushless motor stator winding machine WIND-3-TSM is designed to produce multi poles stator.

Its winding track is in square shape.

It does wires arraying automatically.

It is the best sold needle winding machine during our stator winders

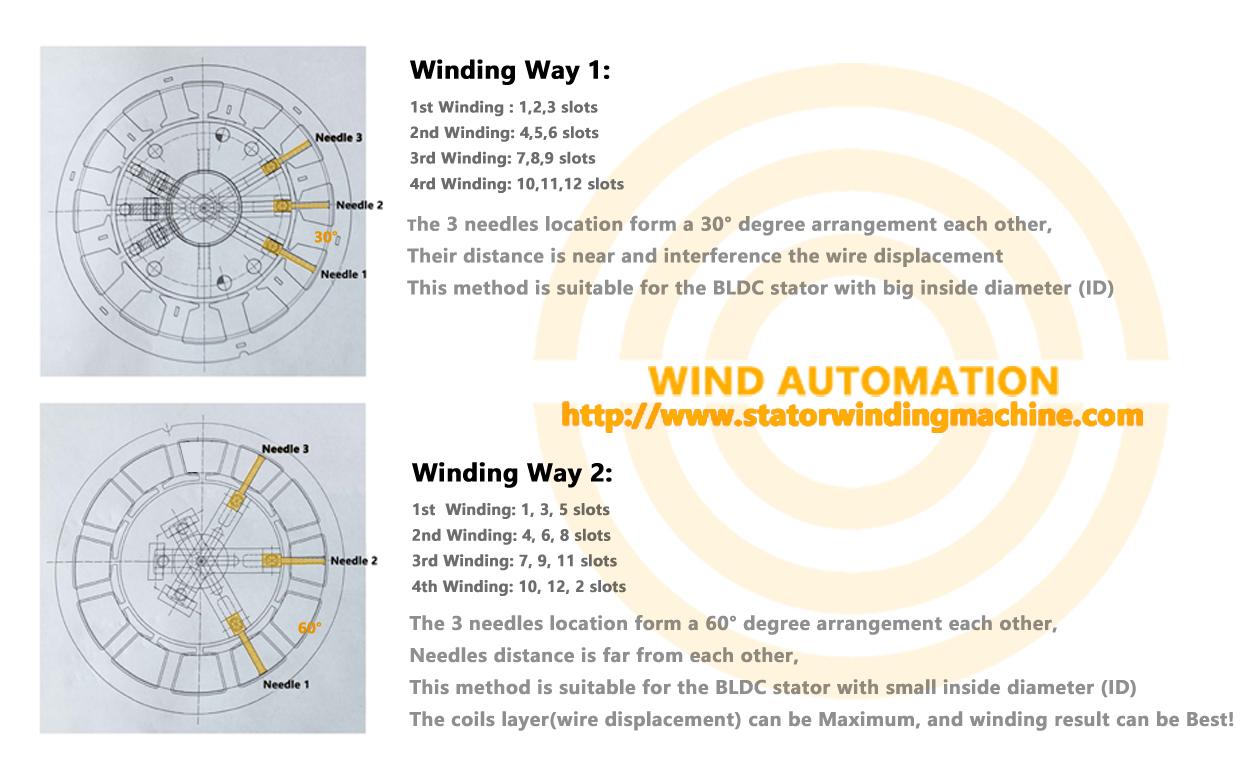

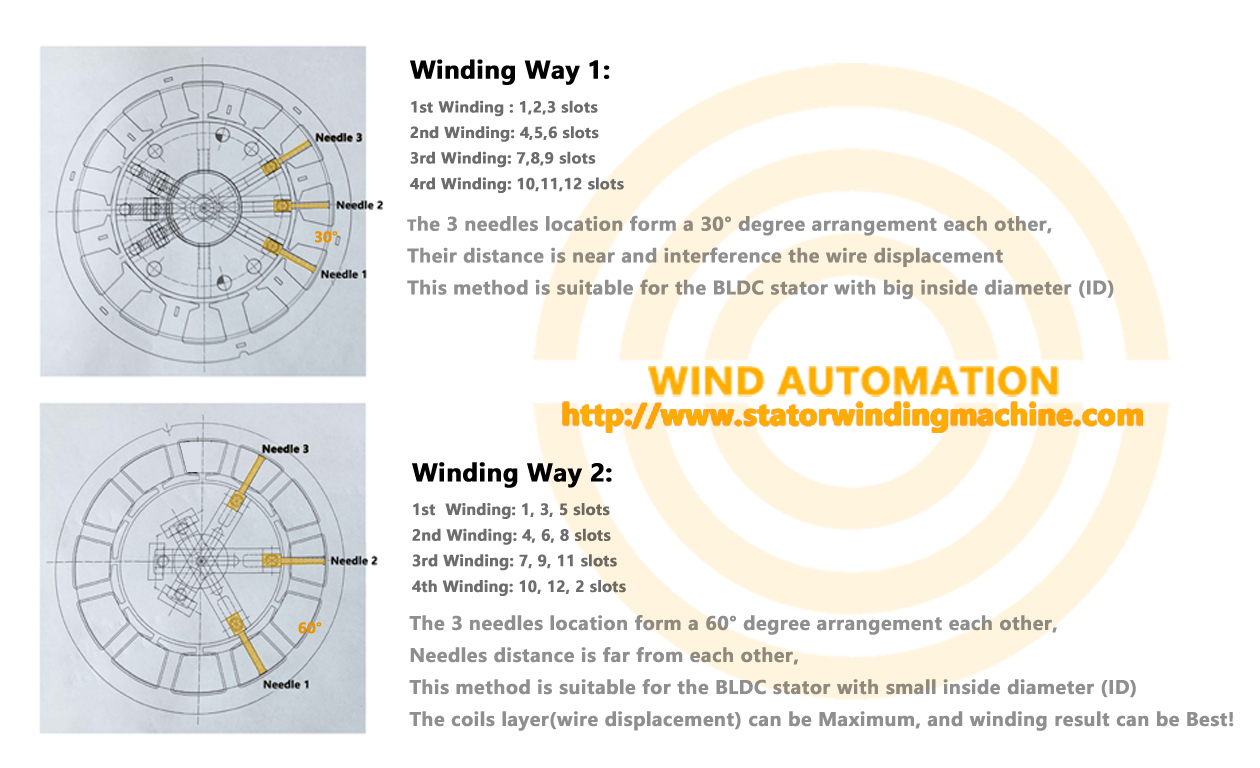

For a 12 slots 3phase stator, the winding way can be 1-4-7-10, 3-6-9-12, 5-8-11-2

1,3, 5slots, 4,6,8 slots, 7, 9, 11slots, 10,12,2 slots,

or 1,2,3 slots, 4,5,6slots, 7,8,9slots, 10,11,12slots

Below is a comparsion of Three Needle Stator Winding Machine Winding Way

Needles

3 needles wind at same time, can finish the winding 2 times for 6poles BLDC stator

Winding diagram

3 phase BLDC motor with same winding way for each phase

Motor applciation

Air conditioning compressor, Refrigerator compressor,water pump automotive application , fuel pump,Model aircraft, medical equipment, household appliances, electric vehicles

Parameter:

Wire diameter:0.08~1.2mm

Stator ID:15~65mm

Core length:7-110mm

Turns No.0-99999

Operation option: stepping/Auto

Stator poles: 6 poles, 9 poles, 12 poles,18poles (Customized)

Air pressure:5~7kg/square centi-meter

Power:2KW, AC220V 50/60Hz

Weight: about 450kgs

Dimension: 1600(L)x1100(W)x1400(H)mm

Video:

Needle winding machines for winding stator of 6pole BLDC motor

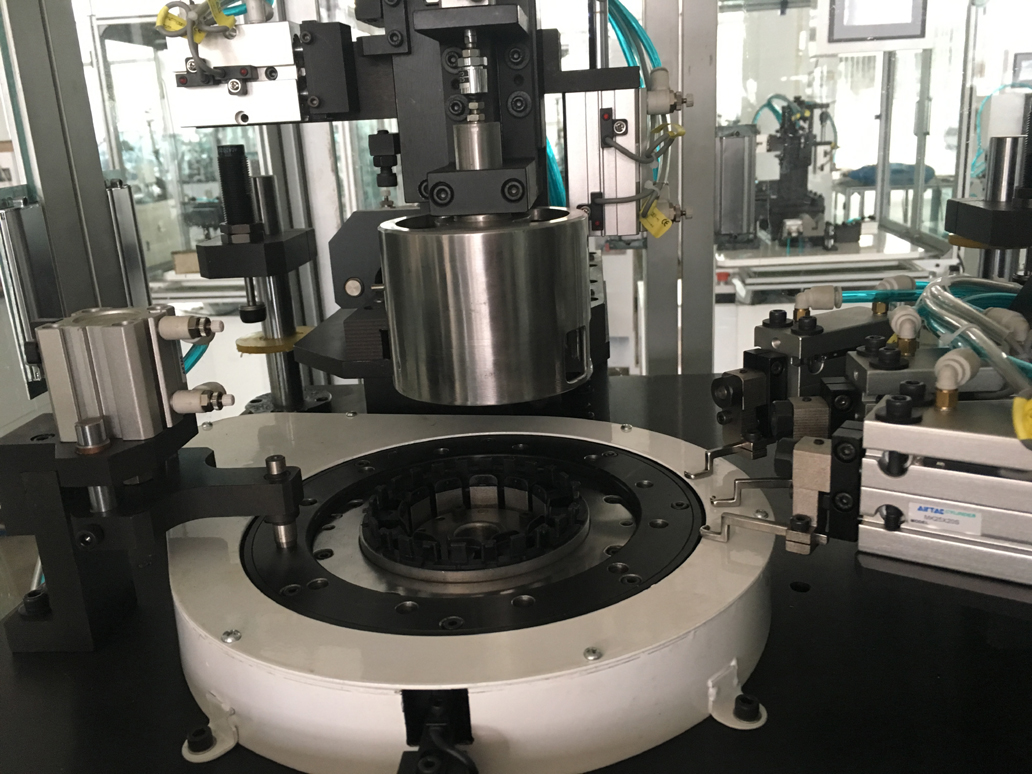

Stator needle winding machine

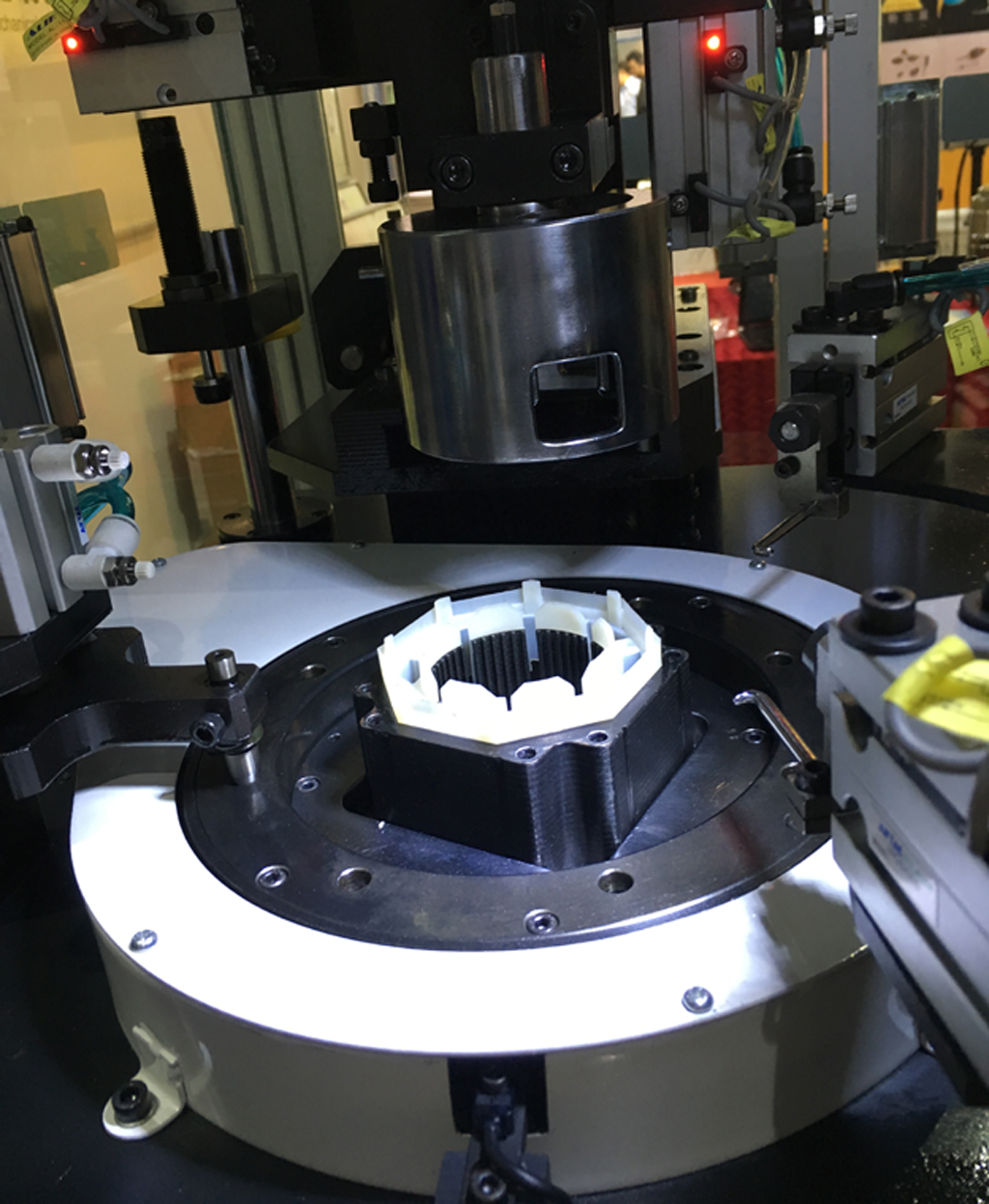

Inslot stator needle winding machine tooling

12 slots stator needle winding

You may also interest in

4 Poles shaded stator needle winding machine(Wind four pole at one time)

BLDC stator flyer winding machine

Contact:Shanghai Wind Automation Equipment Co.,Ltd

Email: [email protected]

Skype: motor.machinery

Mobile: +86-18067425780

Website: http://www.motor-machinery.com; http://www.coilswinding.com

| Parts list WIND-3A-TSM Stator needle winding machine | ||||

| Name | Spec. | Q'ty | ||

| Parts | ||||

| 1 | Spindle belt | HTD8M-776 | 1pc | |

| 2 | Arraying belt | HTD8M-624 | 1pc | |

| 3 | Belt | HTD5M-825 | 1pc | |

| 4 | Fuse | RT18-32 2A | 2pcs | |

| 5 | Fuse | RT18-32 10A | 2pcs | |

| 6 | Magnetic switch | AL-11RL-02 | 1pc | |

| 8 | Ceramic wheel | ∮4 | 1pc | |

| Tools: | ||||

| 1 | Allen wrench | 8pcs | 1Set | |

| 2 | Open end wrench | 13-16mm | 1pc | |

| 3 | Word screwdriver | 4inches | 1pc | |

| 4 | Phillips screwdriver | 4inches | 1pc | |

| 5 | Wrench | 8pcs | 1Set | |

| 6 | Tool box | 1pc | ||

| 7 | Diagonal pliers | 1pc | ||

| Custom part | ||||

| 1 | Nozzle | 1pc | ||

Stator Needle Winding Machine Question and Answer:

1. What is capacity of the muti-pole stator winding machine?

It depends on the turns no. ,wire diameter,slot size and slot no. of your BLDC stators,

WIND-3-TSM is suitable for wire size range from 0.08mm to 1.2mm,

If the BLDC stator wire size is too thin or too thick, you need to wind at a low speed 350RPM~400RPM

If the BLDC stator wire size is normal from 0.5~0.8, you can run the stator needle winder at 400RPM~450RPM

That is for a 12 poles stator, with 105 turns and wire diameter around 0.5~0.8mm,

The cycle time is 60~70s/ps, the productivity per shift is 480pcs/8 hours

2. Can we try our BLDC stator on your needle winding and segmented stator winding machine?

Sorry, the segmented stator winding machine 's tooling is custom made per drawing and sample,

and for needle winding machine for differement segment such as 6poles,9poles,12poles,

their mechanical system such as cam is totally different, and the indexing angle, winding angle is different too.

3. What is advantage of tooth winding machine WIND-3-TSM comparing to other WIND-TSM tooth winding machine type

Three needle winding machine WIND-3-TSM not only wind 3 poles at same time, it is fast with efficiency and place terminal wire to isolation cap also save copper wire and don't need to place terminal wire at end of winding,

Pearl

Pearl Emily

Emily